Heavy machinery is known for its robust performance and durability in various fields such as construction, mining, forestry, and agriculture. These machines work relentlessly and are subject to heavy loads and extreme conditions. However, like any other machine, heavy equipment requires maintenance and regular check-ups to ensure their optimal performance and longevity.

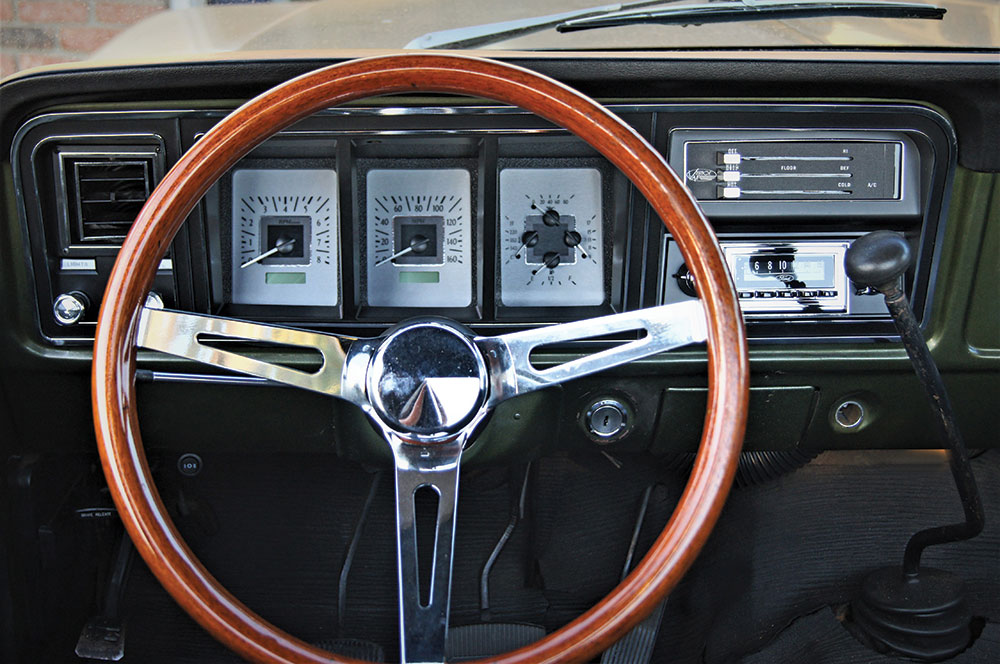

One of the critical components of heavy machinery that requires regular monitoring is the engine temperature. The temperature gauge on the instrument panel is an essential tool that indicates the temperature of the engine coolant. It helps the operator to know if the engine is running hot or cold or if there is any fluctuation in temperature.

However, if the temperature gauge on the instrument panel is not moving at all, it can be a cause for concern. There could be several reasons for this, such as a faulty instrument cluster, broken fuse, or a malfunctioning temperature sensor. In some cases, the thermostat could be stuck open or closed, preventing the coolant from flowing correctly.

Shandong Yingtuo Construction Machinery Co., Ltd. is a well-known enterprise in the construction machinery industry, specializing in the whole machine sales, technical services, parts supply, equipment leasing, and used car business of engineering machinery products. The company understands the importance of regular maintenance and check-ups of heavy machinery.

According to a spokesperson of Shandong Yingtuo Construction Machinery Co., Ltd., "Engine temperature is a critical parameter that affects the performance and longevity of heavy machinery. If the engine temperature is too high, it can cause the oil to break down, damage the engine components, and lead to costly repairs. Therefore, it is essential to monitor the engine temperature regularly and take appropriate actions to prevent any potential damage."

Regular monitoring of engine temperature can be done by checking the temperature gauge on the instrument panel. It is recommended to do it at the start of the day before using the machine and every hour of usage. If the temperature gauge shows any abnormal readings, the operator should take immediate action, such as stopping the machine and investigating the cause of the issue.

In addition to monitoring the engine temperature, regular maintenance of the cooling system is essential to ensure the proper functioning of heavy machinery. The cooling system should be checked for leaks, cracks, and other damages. The coolant level should be maintained at the recommended level and replaced periodically as per the manufacturer's instructions.

Shandong Yingtuo Construction Machinery Co., Ltd. provides technical services and parts supply for engineering machinery products. The company's team of experienced technicians can diagnose and repair any issues related to the engine temperature and cooling system.

In conclusion, monitoring the engine temperature is crucial in the maintenance of heavy machinery. Operators should regularly check the temperature gauge on the instrument panel and take appropriate action if any abnormal readings are observed. It is also essential to maintain the cooling system regularly to prevent potential damages and costly repairs. Shandong Yingtuo Construction Machinery Co., Ltd. offers technical services and parts supply for engineering machinery products to ensure their optimal functioning and longevity.